Economics of Fcv Tobacco Cultivation on Modeland Generalvillage Farms in Prakasam District Of Andhra Pradesh

0 Views

K. PRUTHVI KUMAR, G. V. CHALAM, I. BHAVANI DEVI, AND P. LAVANYA KUMARI

Institute of Agribusiness Management, S.V AgriculturalCollege Campus, Tirupati 517502

ABSTRACT

production of FCV tobacco. Total human labour was 219.83 and 234.45 man days per hectare on FCV tobacco on model village farms and general village farms respectively. On an average the total cost of cultivation per hectare of FCV tobacco was Rs. 143840.56 on model village farms and Rs.153478.27 on general village farms. The net income realized on model village farms was higher with Rs.48659.44 as against with Rs.31396.73 on general village farms.

KEY WORDS: Model villages, general villages, FCV tobacco.

INTRODUCTION

Tobacco called as “Golden Leaf” and one of the important commercial crops of India. in Andhra Pradesh.It provides employment directly and indirectly to 45.7 million people and contributed as much as Rs.22,737.07 crore as excise duty and Rs. 5,975.08 crore in terms of foreign exchange to the National exchequer, during 2016-17. India has a prominent place in the production of tobacco in the world. India stands second in production and export of tobacco in the world. India produces different styles of FCV tobacco, which vary in their physical and chemical characteristics under diverse climatic conditions. Indian tobacco is exported to over 114 countries across the globe. Flue Cured Virginia tobacco which is commercially known as cigarette tobacco, is the most important variety. This variety is mainly cultivated in Andhra Pradesh and Karnataka states (Kalyani, 2012).

FCV tobacco, (Nicotiana tabacum), which is used in the manufacture of cigarettes is called Flue Cured Virginia. It belongs to the family ‘Solananceae’ in natural order. This variety is mainly produced in southern part of the country. It was first introduced to India by Imperial Tobacco Company of India limited during 1910. Since then, India has made tremendous progress in breeding high yielding varieties, improved method of cultivation, economic curing and marketing of virginia tobacco. In India,

*Corresponding author, E-mail:iabm.angrau@gmail.com

MATERIALAND METHODS

The present study was conducted in Andhra Pradesh state. Purposive-cum-random sampling technique was employed for the selection of sample in the present study. Prakasam is the one of the leading districts in Andhra Pradesh regarding cultivation of FCV tobacco. Hence, Prakasam district was purposively selected. The top four mandals with maximum area under cultivation of FCV tobacco and two villages (one model village and one general village) from each mandal based on criterion of highest area under FCV tobacco was purposively selected. All the farmers in selected model villages were listed out and 40 farmers were randomly selected. Another sample of 40 farmers from the general villages were also randomly selected to serve as a control group.The required data for the study were collected from the selected farmersusing a pre-tested schedule for the agricultural year 2016-17.

TOOLS AND TECHNIQUES OFANALYSIS

Simple arithmetic averages and percentages were wo–rked out to arrive at costs, returns and farm efficiency measures (Kuboja and Temu, 2013).

COST CONCEPTS

Cost A1: It includes: Value of hired human labour, value of hired and owned animal labour, value of hired and owned

machine labour, value of seed (both farm seed and purchased), value of manures (owned and purchased)and fertilizers, depreciation on fixed assets, irrigation charges, land revenue, interest on working capital and miscellaneous expenses.

Cost A2: Cost A1 + rent paid for leased in land.

Cost B1: Cost A1+ interest of fixed capital (excluding land)

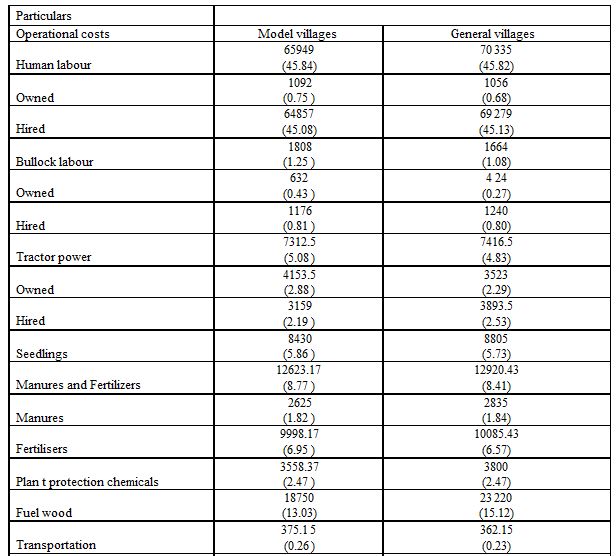

break-up of total costs into operational costs and fixed costs indicated that the operational costs were Rs.121428.63 (84.41 per cent) for model village farmers and Rs.131283.99 (85.53 per cent) on general village farms, while the fixed costs were Rs. 22411.93 (15.59 per cent) and Rs.22194.28 (14.46 per cent) for the corre- sponding farms.Human labour is required to perform vari- ous cultural practices viz., land preparation, sowing, ap- plication of manures and fertilizers and plant protection chemicals, weeding, harvesting, curing and grading

Cost B : Cost B

+ rental value of owned land + rent

(Waheed et al., 2006). Of the total costs, human labour

2 1 was the highest costing input service in the cultivation of for leased in land.

Cost C1: Cost B1 + imputed value of family labour. Cost C2: Cost B2 + imputed value of family labour.

Cost C3: Cost C2+ 10 per cent of cost C2 as management cost.

FARM EFFICIENCY MEASURES

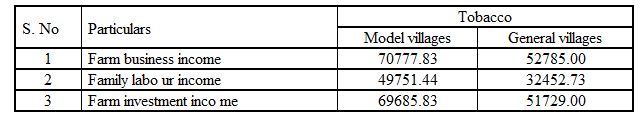

Farm business income = Gross income – Cost A1 Family labour income = Gross income – Cost B2 Net income = Gross income – Cost C3

Farm investment income = Farm business income – imputed value of family labour

(or)

Net income + imputed rental value of owned land + interest on owned fixed capital invested

RESULTS AND DISCUSSIONS

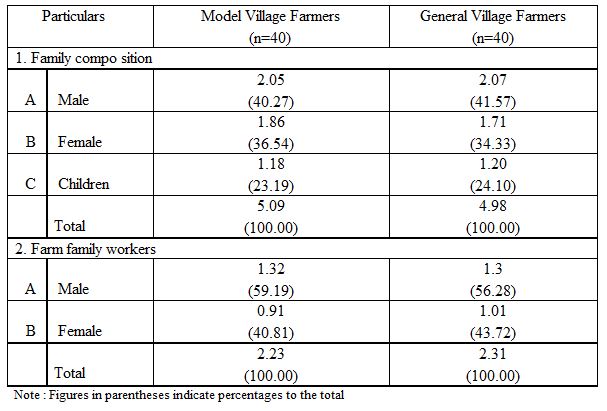

It is observed from Table.1, that the average family size was 5.09 and 4.98 in the case of model and general village farms respectively. The number of family males, females and children was more or less the same in model and general villages. On an average 1.32 male members were available for farm work in model villages, whereas it was 1.30 in general villages. The number of females participating on the farm was 0.91 on model village farms, whereas, it was 1.01 on general village farms. There was no participation of children on the farms.

Total cost of cultivation per hectare of FCV to- bacco was Rs.143840.56 on model village farms and Rs.153478.27 on general village farms (Table.2). The-

FCV tobacco (Tuna et al., 2013). The expenditure in- curred towards this resource service was Rs.65949 (45.84 per cent) for model village farmers and Rs.70335 (45.82 per cent) for general village farmers.Of the total costs the expenditure on machine power input service in the cultivation of FCV tobacco was Rs 7312.5 (5.08 per cent) on model village farms and Rs 7416.5 (4.83 per cent) on general village farms. Fuel was the major item of cost in the cultivation of FCV tobacco amounting to Rs. 18750 (13.03 per cent) for model village farmers and Rs. 23220 (15.12 per cent) for general village farmers. The cost of fuel for model village farmers was less when compared to general village farmers. This is because the model vil- lage farmers used insulators (glass wool turbo) on the top of barnswhich restricts the loss of heat produced inside the barns and results in less consumption of fuel. This installation of insulators was high on the model village farms compared to general village farms.The general vil- lage farmers incurred little more expenditure on plant pro- tection chemicals with Rs. 3800 (2.47 per cent) over model village farmers Rs. 3558.37 (2.47 per cent). Among the fixed costs, rental value of owned land was the major item. It was Rs. 20000 accounting for 13.90 per cent in model village and Rs.18750 (12.21 per cent) in general villages. The other items of fixed costs were land rev- enue, tobacco board license fee, depreciation and inter- est on fixed capital.The analysis of cost structure of FCV tobacco cultivation revealed that it was more for general village farmers over model village farmers.

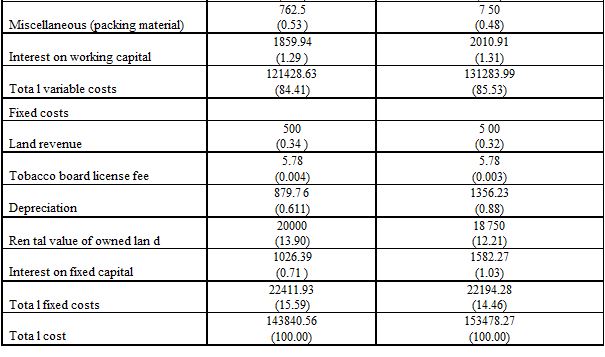

It is clear that from Table.3 there was no leasing in activity among the selected farmers and hence the cost A1 and cost A2 were the same. On an average, the total cost of cultivation (Cost C2) was higher at Rs.153478.27 on general village farms over model village farms (Rs.143840.56).

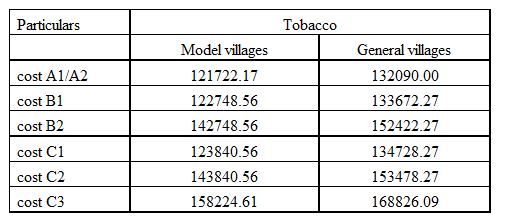

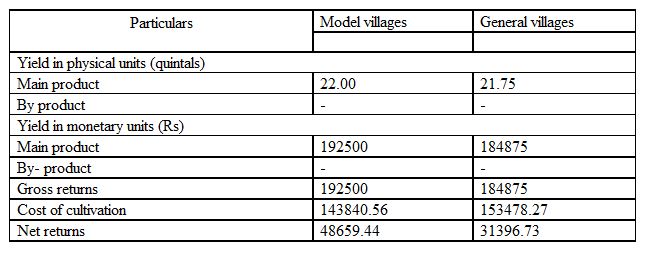

The details of physical output and gross returns per hectare of FCV tobacco crop are presented in Table.4 On an average, the yield of main product per hectare was

22.00 and 21.75 quintals, on model and general village farms respectively. The model and general village farms realized a gross income of Rs.192500 and Rs.184875 respectively. The net income was high on model village farms with Rs.48659.44 compared to Rs.31396.73 on general village farms.

It is clear that from Table.5Model village farms were able to secure Rs.1.33 per every rupee spent, while general village farms received Rs.1.20.Family labour income was another measure of farm efficiency which represents returns to farmers own labour and family labour. Model village farms derived more family labour income of Rs.49751.44 compared to general village farms Rs.32452.73. It was noticed that the model village farms were efficient in utilization of resources in the cultivation of FCV tobacco (Dinesh Kumar et al., 2010). Farm investment income was a measure that indicated returns to fixed capital. It was Rs.69685.83 on model village farms and Rs.51729.00 on general village farms.

CONCLUSIONS

Total human labour was 219.83 and 234.45 man days per hectare on FCV tobacco model and general village farms. On an average the total cost of cultivation per hectare of FCV tobacco was Rs.143840.56 on model village farms and Rs.153478.27 on general village farms. The price per quintal was more on model village farms with Rs.8750 compared to Rs.8500 on general village farms. The gross income realized was higher on model village farms with Rs.192500 as against with Rs.184875 on general village farms. Net income realized was higher on model village farms with Rs.48659.44 as against with Rs.31396.73 on general village farms.

REFERENCE

Dinesh kumar, M., Channanaik, D., Sridhara, S., Vageesh,

T. S., Girijesh, G. K and Rangaiah, S.2010.Investigation on economically viable alternative cropping systems for FCV tobacco (Nicotianatabacum) in Karnataka, Karnataka Journal of Agricultural Sciences.23(5): (689- 692).

Kalyani, K., Suman Naidu, S.K., Nageswara, S and ArunaKumari, N.2012.Changing socio-economic scenario of FCV tobacco farmers in NLS areas of Andhra Pradesh.Acadamic Journal of Agricultural Science Digest. 32(1): 58-60.

Kuboja, N.M and Temu, A.E. 2013.A comparative economic analysis of tobacco and groundnut farming in Urambo district, Tabora region, Tanzania.Journal of Economics and Sustainable Development. 4(19): 104-111.

Tuna, E., Georgiev, N and Nacka, M. 2013. Competitiveness analysis of the tobacco sub sector in the Republic of Macedonia.Agro EconomiaCroatica. 3(1): 53-60.

Waheed,Q.,Khan,N., Ashfaq, Furqan,M.A., and Muhammadidress.2006.Economics of tobacco production in Swabi district, WFP.Journal of Agricultural and Biological Sciences.1 (3): 30-35.

Table.1 Family composition and family labour contribution on selected farms (in number)

Table.2 Cost of cultivation of FCV tobacco component wise on model and general village farms

(rupees ha-1)

Table.3 Cost concepts in FCV tobacco on model and general village farms ( Rs per ha)

Table.4 Output and returns per hectare of FCV tobacco on model and general village farms

( Rs.per ha)

Table.5 Measures of farm income in FCV tobacco cultivation on model and general village farms (Rs. per ha)

- Bio-Formulations for Plant Growth-Promoting Streptomyces SP.

- Brand Preference of Farmers for Maize Seed

- Issues That Consumer Experience Towards Online Food Delivery (Ofd) Services in Tirupati City

- Influence of High Density Planting on Yield Parameters of Super Early and Mid Early Varieties of Redgram (Cajanus Cajan (L.) Millsp.)

- Influence of Iron, Zinc and Supplemental N P K on Yield and Yield Attributes of Dry Direct Sown Rice

- Effect of Soil and Foliar Application of Nutrients on the Performance of Bold Seeded Groundnut (Arachis Hypogaea L.)