Constraints in Greenhouse Crop Production in Chittoor District of Andhra Pradesh, India

0 Views

TIPPU SULTAN*, N. VANI, RAMANA MURTHY AND I. BHAVANI DEVI

Department of Agricultural Economics, S.V. Agricultural College, ANGRAU, Tirupati

ABSTRACT

An attempt has been made to study constraints faced by the greenhouse farmers in Chittoor district. For this purpose, five mandals were selected based on highest average number of greenhouses. The data were collected from each respondent through personal interview method with the help of structured questionnaire during 2019-20. Garrett ranking technique was employed to analyze each of the constraints affecting the adoption of greenhouse technology. To sustain the self-sufficiency in food production we need effective technologies, which can improve the productivity and sustainability of our major farming systems. Greenhouse technology, one among improved technologies that ensures stability in agriculture production.

KEYWORDS: Greenhouse, factors, Environmental constraints.

INTRODUCTION

Protected cultivation also sometimes called as greenhouse cultivation. In the present situation of everlasting demand for enhanced quality horticultural crops and continuously lessening land holdings, greenhouse technology is the finest choice for efficient use of land and other resources. Crop yields can be numerous times higher than those under open field conditions, greater quality, higher input use efficiencies are realized and export can be heightened.

With the innovation in agriculture, various types of protected cultivation practices appropriate for a specific type of agro-climatic zone have materialized. Among these protective cultivation practices, Glasshouse, Green house, Plastic house/ Greenhouse, Lath house, Cloth house, Net house, shade house, cold frames and hot beds etc. is useful for the Indian conditions.

In Indian Horticulture, there is significant increase in production of horticultural produces with a total amount of more than 311.71 million tonnes and India ranks second in horticultural production in world next to China (NHB, 2018). In spite of second largest producing country there is low productivity in India which is due to the adverse climatic conditions like varying range of temperature from 0-480C during the year which does not allow year round cultivation of vegetable in open condition. Availability of large quantity produce in market during growing season. Day by day there is increasing in demand for high quality vegetables and availability of vegetables round the year, which can either be fulfilled by early and late cultivation or off-season cultivation adopting protected cultivation. Presently, progressive farmers are adopting commercial protected cultivation of high value vegetables and flowers (Maitra, 2020).

MATERIAL AND METHODS

Chittoor district will be purposively selected on the basis of predominance of greenhouses. Proportionate random sampling will be used in selecting the greenhouses located in various mandals of the district. 30 greenhouse units will be selected for study. Major crops cultivated under greenhouse units were selected for the study. Primary data will be collected for the agricultural year 2019-20 through personal interview with the help of a well-structured schedule formulated based on objectives. It includes establishment costs of greenhouses, material and labour resources used , costs and returns of greenhouse crops, factors influencing production and marketing of greenhouse crops and problems experienced by greenhouse farmers. Garrett ranking technique was employed to analyze the data and arrive at valid conclusions

RESULTS AND DISCUSSION

In the present study, some of the important constraints faced by greenhouse farmers in production of capsicum and chrysanthemum crops of Chittoor district was studied in the following sub-heads.

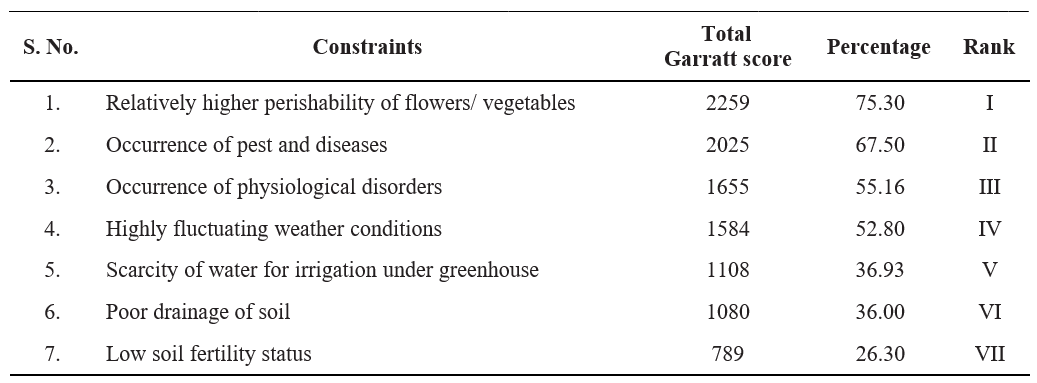

Environmental Constraints

The environmental constraints faced by farmers in adoption of greenhouse technology were presented in Table 1. The constraint faced by farmers under the environmental constraints is the relatively higher perishable flowers/vegetables (75.30%) and i ranked in first position. The perishable nature of produce from the greenhouses demands immediate disposal into the markets. Otherwise the quality of produce is deteriorated. Occurrence of pest and diseases was ranked second (67.50%). Due to more incidence of pest and diseases inside the greenhouses exceeds relatively more to open cultivation because of high moisture and high humidity inside the greenhouse. Occurrence of physiological disorders ranked third position (55.16%), followed by highly fluctuating weather conditions under greenhouse (52.80%), Scarcity of water for irrigation under greenhouse (36.93%), poor drainage of soils (36.00%), due to irrigation through drip inside the greenhouse has led to poor drainage conditions. and low fertility status of soil was ranked VII Seventh (26.30%). The results are similar to Paroda (2013) who reported that among the major environmental constraints in production of horticultural crops in India are temperature, duration and quality of sunlight, surplus or scarcity of water, atmospheric moisture, weeds, physiological disorders, heavy winds, carbon dioxide and incidence of pest and diseases.

Table 1. Environmental constraints as faced by farmers in adoption of greenhouse technology

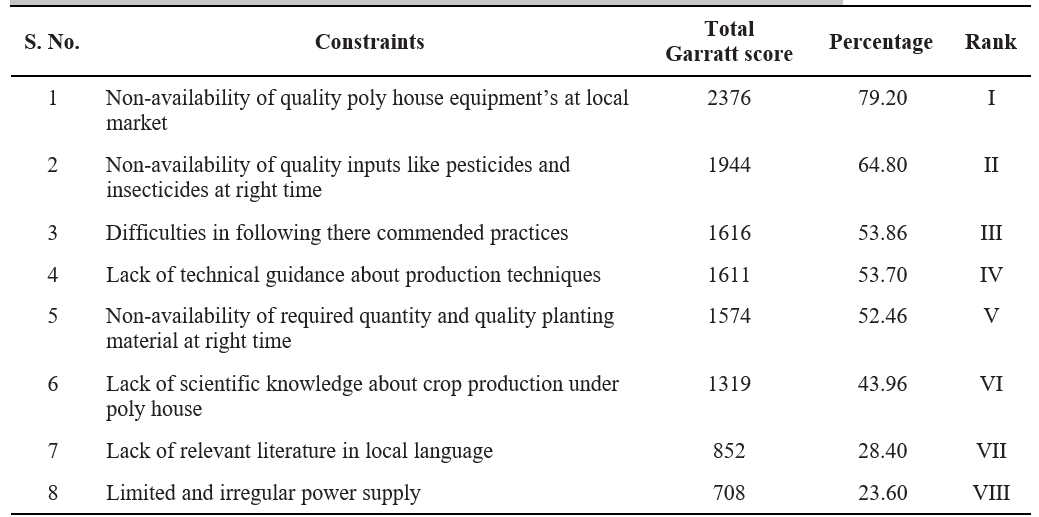

Technical Constraints

High knowledge and skill intensive technology are prerequisites for greenhouse technology. The various technical constraints faced by greenhouse farmers were presented in Table 2. Farmers expressed that the non- availability of quality poly house equipment’s at local market was ranked first (79.20%), followed by non- availability of quality inputs like pesticides and insecticides at right time (64.80%), difficulty in following the package of practices for cultivation of crops under greenhouse (53.86), lack of guidance about the production techniques (53.70%), non-availability of quantity and quality planting material at right time (52.46%), lack of scientific knowledge about crop production under poly house (43.96%), lack of relevant literature in local languages (28.40%), and limited and irregular power supply (23.60%), is ranked least among the technical constraints as the required power is being supplied to the greenhouse farmers. The results are in conformity with the results obtained by Manjunath et al. (2015) where in it was reported that availability of quality seed and planting material of required cultivar is a severe constraint faced by farmers on account of increased dependence on formal sector especially private seed companies. Similar results are also reported by Singh and Sirohi (2006) where in it was reported that no specific breeding work had been initiated for development of suitable varieties for protected cultivation even in important vegetables, viz., tomato, cherry tomato, sweet pepper and cucumber.

Table 2. Technical constraints as faced by farmers in adoption of greenhouse technology

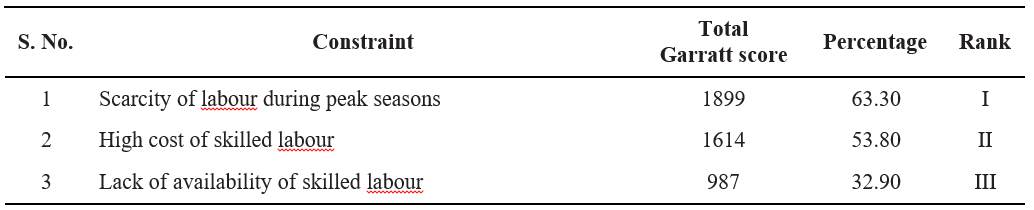

Labour Constraints

Greenhouse cultivation of crops demands skilled labour and intensive labour throughout the year. Availability of skilled labour is a major issue due to migration from rural to urban areas in search of better employment opportunities and indifferent attitude of youth towards agriculture has led to shortage of skilled labour and which has naturally raised the wage rates of

skilled labour required for greenhouse cultivation. The labour constraints faced by farmers were presented in Table 3. Scarcity of labour during peak season was ranked first (63.30%), followed by high cost of skilled labour (53.80%) and lack of availability of skilled labour (32.90%). The results are in conformity with the findings of Prabhakar et al. (2017).

Table 3. Labour constraints as faced by farmers in adoption of greenhouse technology

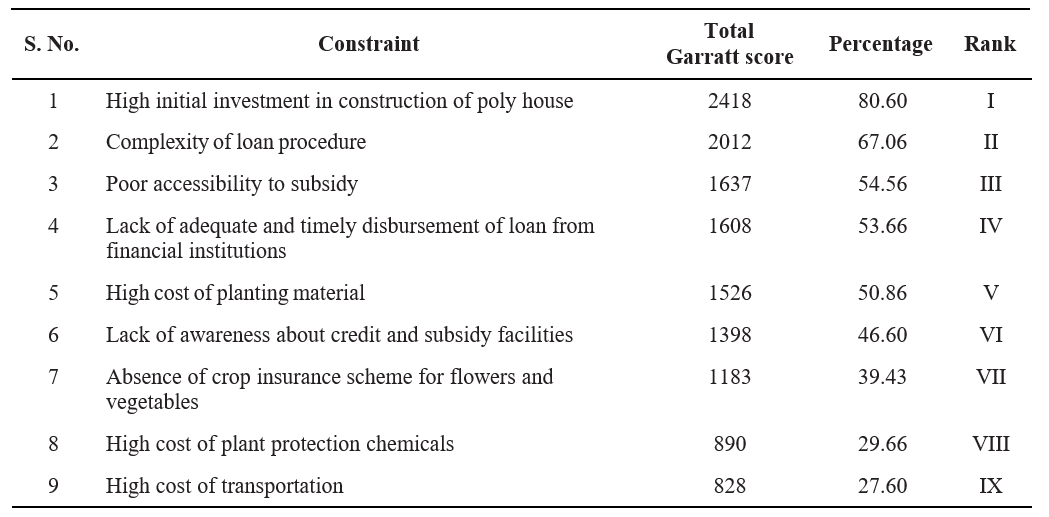

Economic Constraints

The economic constraints faced by the greenhouse farmers in adoption of greenhouse technology were presented in Table 4. High initial investment in construction of poly house was ranked first (80.60%), as the initial investment required to establish a greenhouse is very high and is beyond the reach of small and marginal farmers. Singh and Sirohi (2006) also reported that the basic cost of fabrication and the operation cost of the climate-controlled greenhouses are very high.

The farmers expressed that it took minimum of 8 months after submission of loan application, to avail loans facilities from financial institutions and commercial banks and hence complexity of loan procedure is ranked second (67.06%), poor accessibility of credit was ranked third (54.46%), followed by lack of adequate and timely disbursement of loan from financial institutions (53.66%), high cost of planting material (50.86%), lack of awareness about credit and subsidy facilities (46.60%), absence of crop insurance scheme for flowers and vegetables (39.43%), high cost of plant protection chemicals (29.66%), and high cost of transportation (27.06%).

Greenhouse cultivation of crops requires quality-planting material, inputs etc, which adds economic burden to the farmers and the upper ceiling limit of subsidy, varies from scheme to scheme but generally it ranged from 20 to 50 percent of the cost of erection of greenhouse.

Table 4. Economic constraints as faced by farmers in adoption of greenhouse technology

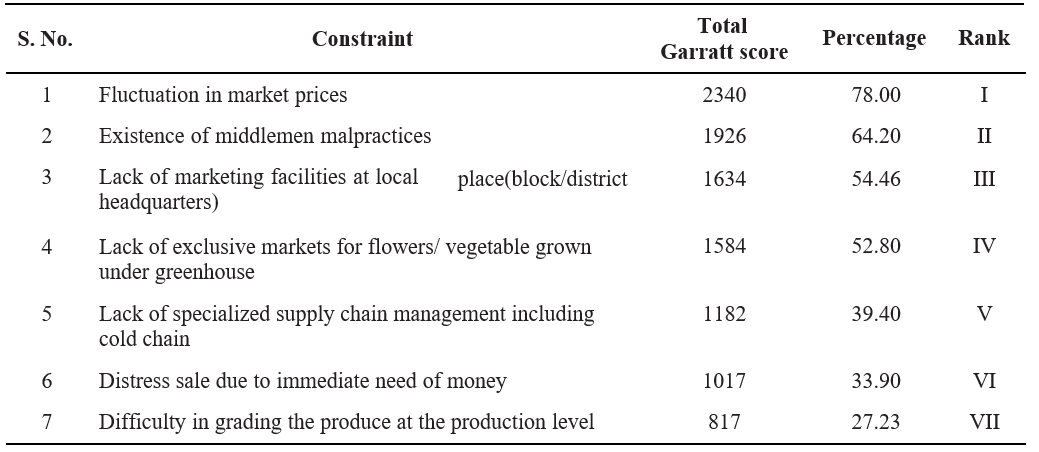

Table 5. Marketing constraints as faced by farmers in adoption of greenhouse technology

Marketing constraints

The marketing constraints faced by the greenhouse farmers in adoption of greenhouse technology were presented in Table 5. Fluctuations in market prices was ranked first (78.00%), followed by existence of middlemen malpractices (64.20%), lack of marketing facilities at local place (54.46%), lack of exclusive markets for vegetables/flowers grown under greenhouse (52.80%), lack of specialized supply chain management including cold chain (39.40%), distress sale due to immediate need of money (33.90%), and difficulty in grading the produce at production level (27.23%). The deficiencies in the infrastructure such as poor grading, transport facilities and cold chain management combined with malpractices were added to the risk component of the greenhouse farmers.

CONCLUSION

While analyzing overall constraints faced by the greenhouse respondents, it was found that higher perishability of flowers and vegetables, non-availability of quality poly house equipment’s at local market, scarcity of labour during peak season, high initial investment in greenhouse establishment and fluctuations in greenhouse crops prices were the major constraints faced by greenhouse farmers in study area.

LITERATURE CITED

Maitra, S., Biplab, M., Rupak, S., Ranjit, C., Surajit, K and Om Prakash, C. 2020. Small scale protected cultivation for off-season vegetables: A promising option for terai farmers towards. Income Generation. International Journal of Current Microbiology and Applied Sciences. 9(4): 972-980.

Manjunatha, B.L., Rao, D.U.M., Sharma, J.P., Burman, R.R., Dipika, H., Dastagiri, M.B and Sumanthkumar, 2015. Factors affecting accessibility, use and performance of quality seeds in Andhra Pradesh and Bihar: Farmers’ experiences. Journal of Community Mobilization and Sustainable Development. 10(1): 130–45.

National Horticultural Board. 2018. Ministry of Agriculture and Farmers Welfare, Government of India, New Delhi.

Paroda, R.S. 2013. Strategies for protected cultivation. Inaugural Address, delivered at the first National Seminar on Advances in Protected Cultivation, at NASC Complex, Pusa Campus, New Delhi.

Prabhakar., Vijayaragavan, K., Premlata Singh., Balraj Singh., Janakiram., Manjunath, B.L., Seema, J and Sekar, I. 2017. Constraints in adoption and strategies to promote polyhouse technology among farmers a multi-stakeholder and multi-dimensional study. Indian Journal of Agricultural Sciences. 87(4): 485- 90.

Singh, B and Sirohi, N.P.S. 2006. Protected cultivation of vegetables in India: Problems and future prospects. In International symposium on greenhouses, environmental controls and in-house mechanization for crop production in the tropics and sub-tropics. ISHS Acta Hort. 710.

- Bio-Formulations for Plant Growth-Promoting Streptomyces SP.

- Brand Preference of Farmers for Maize Seed

- Issues That Consumer Experience Towards Online Food Delivery (Ofd) Services in Tirupati City

- Influence of High Density Planting on Yield Parameters of Super Early and Mid Early Varieties of Redgram (Cajanus Cajan (L.) Millsp.)

- Influence of Iron, Zinc and Supplemental N P K on Yield and Yield Attributes of Dry Direct Sown Rice

- Effect of Soil and Foliar Application of Nutrients on the Performance of Bold Seeded Groundnut (Arachis Hypogaea L.)